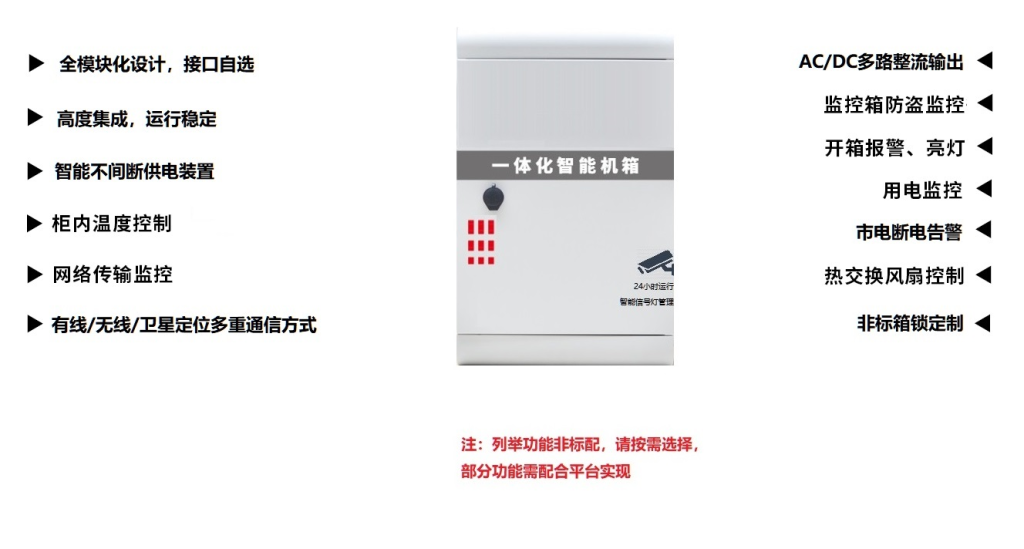

All-in-one intelligent pole-holding chassis

Highly integrated:

Set chassis, equipment information acquisition and remote control, Internet of Things sensors, power supply module, lightning protection, network communications, using MCU architecture integrated control, all sensor protocols using a line output box without additional cables and circuit interference.

Zero interruption function (optional):

In any case of external power supply failure, can ensure the normal operation of various voltage devices inside the cabinet, and timely alarm to the center, configure various power industrial lithium modules, does not take up additional space.

Flexible deployment and easy maintenance:

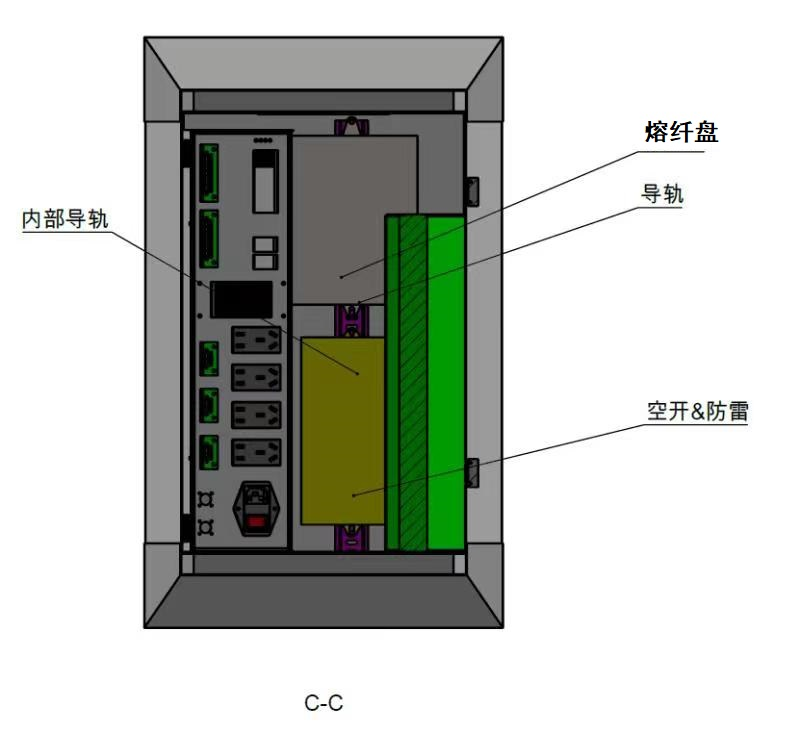

All functional units are factory preset, the implementation of the site only need to introduce fiber optic, network, data, power lines into the box and the box preset interface docking, no need to dismantle the box board, modules to complete the deployment.

High reliability:

Follow the industrialization standard, all electronic components of the whole machine are in line with industrial wide temperature standards, the motherboard is covered with adhesive aging treatment, adapted to -40 to 95 degrees Celsius outdoor working temperature, no need for air-conditioned environment, anti-surge breakdown and electromagnetic interference, can be wall-mounted and hoop mounted.

SMART-PHB IGXXGMC series integrated intelligent holding rod chassis is our company according to the construction of smart city, car networking, intelligent transportation, environmental protection and other fields of digital infrastructure transformation needs, independent research and development of intelligent power supply with industrial Internet characteristics of communication aggregation products, and has declared a national patent. This product is a new type of remote access equipment for outdoor use specially developed and manufactured to meet the needs of users for remote intelligent control of road intelligent equipment, which includes anti-surge system, power conversion system, AC/DC power control and metering system, data acquisition system, network routing and switching system, and remote control system, etc., and works with the third-party terminal equipment management platform system. Its design gives full consideration to the multifunctionality and stability, based on ARM Microcontrollers technology architecture design, can meet the various types of intelligent terminal equipment data collection and intelligent control, at the same time have a certain degree of scalability, easy to realize the different protocols under the existing hardware of the new equipment access, can be deployed individually or integrated in the communication box, to meet the original holding pole communication box a variety of functional requirements, combined with the existing scenarios and so on. Functional requirements, combined with the characteristics of the existing scene, as well as the future demand for information management, increase the application of Internet of Things communication technology, the use of modular layout, perfect network management functions and timely status display to ensure the reliability of the entire system, continuity and intelligence, has been successfully applied to public security and traffic police departments.

1.1 Intelligent center control power supply

When the utility input, it can provide multiple power outputs of different specifications (AC220V, DC24V, DC12V) at the same time, without the need for additional transformers, while the input side comes with a filter function.

All power outputs have over-current, over-voltage, short-circuit protection, can directly output the current and voltage of each power supply to the command center (optional), so that the owner can respond to emergencies in a timely manner, and can be installed with a remote module to control the power supply of each way to turn on and off. This function is especially suitable for the electronic police, cardinal points, monitoring, signal lights and other key business power needs, also applies to remote areas or high speed and other scenarios that are not easy to deal with the failure of the scene in a timely manner, in the hot weather remote restart of the terminal equipment in order to reduce the failure rate:

- Multi-way power supply: provide AC220V, DC24V, DC12V and other output interfaces, adapted to all kinds of cameras, radar, signaling machines, vehicle inspectors, switches, routers, composite detectors and other equipment centralized local power supply;

- Under-voltage protection: realize automatic cut-off of battery discharge output when battery voltage is under-voltage, under-voltage protection to prevent battery over-discharge;

- Data output: output all data to PLC or center backend through RJ45 interface without relay or secondary protocol conversion; including the current and voltage of power supply, as well as temperature and humidity and other types of values;

- One-key switch: Configure a separate power start switch with lightning strike and instantaneous current overload protection;

- Intelligent management: fully automatic control of fully automatic switching without human intervention, AC power outage signal output for the user, the background man-machine interactive visualization interface displaying the remaining power value and standby time (requires additional secondary development);

1.2 Data Acquisition and Remote Control

1、Box status detection function;

- Temperature and humidity detection: real-time acquisition of local display temperature and humidity, and upload the temperature and humidity inside the box; according to the set temperature and humidity upper and lower limits to control the fan start and stop. At the same time, the box temperature is too high local alarm.

- Box door status detection: real-time detection of the box door status, box door illegal open alarm; box door open, through the center of the authorization mode or enter the password to achieve delayed alarm.

- Box illumination detection (optional): real-time detection of box illumination, realize intelligent opening of box lighting.

- Box flood monitoring (optional): collect and upload water leakage inside the box.

2、Box equipment detection function:

- Fan operation status detection: you can remotely check the fan operation status.

- Power supply detection: real-time monitoring and uploading of voltage and current status and values.

- Circuit breaker status detection (optional): real-time detection of circuit breaker closing status, tripping times, tripping types (additional separate configuration).

- Network communication unit status detection: real-time detection of optical switch network communication, power supply, fiber optic interface status.

3、Remote control function (optional):

- Brightness adjustment of the police light: the brightness of the police light on the pole can be adjusted remotely and locally according to the actual situation.

- Fan control: remote control of fan start and stop.

- Lighting control: remote control of lighting switch.

- Circuit breaker control: remote power failure restart can be realized.

- Individual socket single-channel restart: can realize the remote restart of each socket switch.

1.3 Network Communications

The network communication unit has a maximum of 12 Gigabit interfaces. It is used to access the terminal equipment such as cameras and radars installed on the crossbar, and converge to the intersection convergence switch through fiber optic to transmit the data to the central server room.

Port Characteristics

- Optical ports: default is 4 100/1000Mbps SFP slots (module can be configured single-mode dual-core or single-mode dual-core 10km-80km);

- Electrical ports: the default is 8 10/100/1000Base-T (X) adaptive Ethernet RJ45 ports, can be expanded to 20 Gigabit electrical ports

- CONSOLE port: RJ45 interface

Transmission Distance

- Twisted pair cable: 100m

- Optical fiber: 10KM, 20KM, 40KM, 60KM, 80KM and other options

Technical Parameters

- Protocol standard: IEEE 802.3i/802.3u/802.3ab/802.3z/802.3x/802.3ad/802.1p/802.1q

- /802.1d/802.1w/802.1s/802.1ad/802.3az/802.1x/802.1ab, etc.

- Flow control: 3x flow control, back pressure flow control

- Transport mode: store-and-forward

- Switching Attributes: VLAN:4K, MAC Table:8K, Cache:12Mbit, Latency:<5µS,

- Backplane Bandwidth: 24Gbps Packet Forwarding: 17.8Mpps

- Alarm connection: Phoenix terminal;

- Power protection: supports reverse connection protection, over-voltage protection, over-current protection, and alarm output;

- Rated power: ≤ 30W;

Environmental Characterization

- Operating temperature: -40℃~+85℃, Storage temperature: -40℃~+85℃.

- Relative humidity: 5~95% (no condensation)

Accreditation

1.4 lightning Protection

The box is equipped with AC 220V lightning protection and network lightning protection function, which can provide 1 channel AC 220V strong electricity and multi-channel network lightning protection.

- Powerful protection capability: AC 220V lightning protection module with a maximum: 40kA (8/20us) discharge current surge discharge capability; network lightning protection with voltage protection level Up: line – ground 600V, line – line 25V ability to withstand C2: 5kV/2.5kA composite wave test.

- AC 220V lightning protection unit features: built-in instantaneous overcurrent disconnection device, with a remote alarm interface, failure detection instructions, built-in thermal disconnection device, standard modular installation.

1.5Extended Functionality

The following functions can be customized and extended:

1、Monitoring the DC (AC) power supply single circuit working status;

2、Bluetooth unlocking certification;

Item | Properties | Specification |

|

|

|

General Index | Shell material | Cold rolled steel plate, plate thickness 1.2mm, anti-corrosion and anti-rust coating |

Touch screen operation | Display temperature and humidity, current, voltage, LOGO, etc. | |

Standard accessories | Temperature and humidity sensor, laser proximity switch, optical fiber tray, distribution box | |

Installation | Wall-mounted, pole-holding | |

Motherboard performance | Processor Type | ARM Microcontrollers – MCU |

Core | ARM Cortex M4 | |

Data Bus Width | 32 bit | |

Program Memory | 512KB | |

Data RAM | 192KB | |

Power Index | Rated Input Voltage | 100-240VAC |

Operating Range | 90-264VAC | |

Rated Input Frequency | 50/60Hz | |

Starting inrush current | ≤60A | |

Maximum input current | ≤1.8A | |

Efficiency | ≥88% | |

PF value | ≥0.4 | |

No-load power consumption | ≤30W | |

Rated output voltage | 4-channel 12VDC, 4-channel 24VDC, 4-channel 220VAC | |

Number of output channels | 12-way conventional, can be customized | |

Undervoltage protection | Realize automatic cut-off of battery discharge output when the battery voltage is undervoltage, undervoltage protection to prevent battery over-discharge; | |

One key switch | Configure a separate power start switch with filtering, lightning protection and instantaneous current overload protection. | |

Intelligent control | Fully automatic control of fully automatic switching without human intervention, AC power outage signal output for the user, the background visualization interface shows the value of the remaining power and standby time and alarm (requires secondary development) | |

Short circuit protection | Output short-circuit does not damage the product, short-circuit elimination to restore normal output | |

Electromagnetic compatibility standards | MEET GB4943.1-2011, GB17625.1-2012;GB/T9254-2008 | |

Overcurrent disconnecting action time | 3±0.5 s | |

Short-circuit disconnecting action time | ≤0.1 s | |

Leakage disconnection action time | ≤0.1 s | |

Data Acquisition and Remote Control | Output | 1 x 10M/100M/RJ45 port |

Fan Control | Optional | |

Door status | 1 channel as standard | |

Lighting control | Option | |

Temperature and humidity monitoring | Standard 1 channel | |

485 output | 1 channel as standard | |

Uninterruptible power battery port | Optional | |

Lithium battery pack | 200W/500W optional | |

Water level detection port | Option | |

Temperature and humidity measurement range | Temperature: -40℃~+95 Humidity: 0~100%rh | |

Temperature and humidity measurement accuracy | Temperature: ±0.3℃ Humidity: ±2%rh | |

Standard Sensor | Temperature and humidity sensor, laser proximity sensor | |

Network Communication Performance | Access Method | 10/100/1000Mbps |

Optical wavelength | 850nm/1310nm/1550nm | |

Transmission distance | Category 5 twisted pair: 100m Dual-fiber multimode: 300m Dual-fiber single mode: 25/40/60/80/100/120Km Single fiber single mode: 25/40/60/80/100Km | |

Ports | Not less than 8 RJ45 ports: connecting STP/UTP Category 5 twisted pair. | |

Not less than four SFP optical module interface: dual-fiber multi-mode SC/ST/FC (fiber size 50,62.5/125μm); dual-fiber single-mode SC/ST/FC (fiber size 9/125μm); single-fiber single-mode SC/FC (fiber size 9/125μm) | ||

Conversion mode | Media conversion, store-and-forward/straight-through | |

MAC address table | 8K | |

Cache | 12 Mbit | |

Flow control | Full-duplex state: flow control, half-duplex state: backpressure mode | |

Switching Capacity | 24Gbps | |

Packet Forwarding Rate | 17.8Mpps | |

LED Indicators | Power: P1, P2; System Run/Ring Indication: R; Alarm: A; Interface: Link/Act (Optical) | |

Protection Grade | IP41 | |

Power lightning protection Performance | Maximum sustainable working voltage | Uc:385V AC |

Nominal Discharge Current | In:20kA(8/20us) | |

Maximum discharge current | Imax:40kA(8/20us) | |

Voltage protection level | Up:1700V(In下) | |

Response time | Ta:25ns | |

Reference Standard | GB18802.1 2010 YD1235 IEC61643 | |

Network lightning protection Performance | Maximum sustainable working voltage | Uc:6V |

Complex wave test | C2:5kV/2.5kA | |

Voltage Protection Level | Up:Line-earth 600V Line-line 25V |

- Box: cold-rolled steel plate, thickness not less than 2mm, anti-corrosion plastic spraying process, the use of holding bar installation form

- Size: box internal space not less than 320 * 250 * 500 (length, width and height)

Processor data bus width: 32bit - Power supply interface: integrated panel, AC220V not less than 4-way national standard five-hole socket, DC24V not less than 4-way, DC12V not less than 4-way;

- Data interface: configure temperature and humidity monitoring port, fan intelligent linkage port, chassis door monitoring port, 485 port each 1 way;

- Network interface: not less than 8 Gigabit RJ45 port, not less than 4 Gigabit SFP optical module interface;

- Communication performance: backplane bandwidth: not less than 24Gbps packet

- forwarding: not less than 17.8Mpps

- Basic functions: support VLAN, STP, RSTP, MSTP, ACL, QOS, port aggregation, redundant port configuration, LLDP and other functions;

- Routing function: supports IPv4 and IPv6 static routing protocols;

- Protection level: IP44

Embedded industrial touch screen needs to be configured, the menu needs to display real-time temperature and humidity, current and voltage, switching status and other status, and administrator password needs to be set;

For EMC, protection level data need to provide CNAS qualified third-party testing organizations issued test reports.